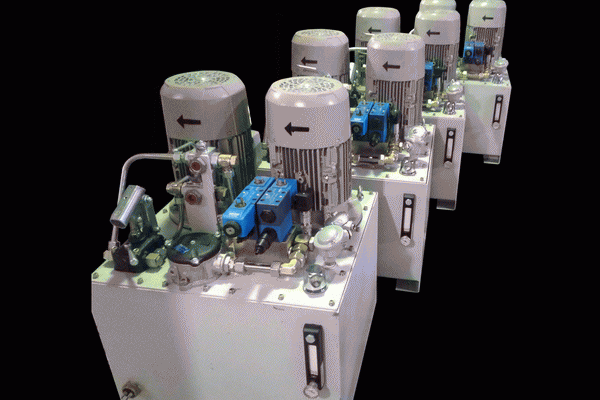

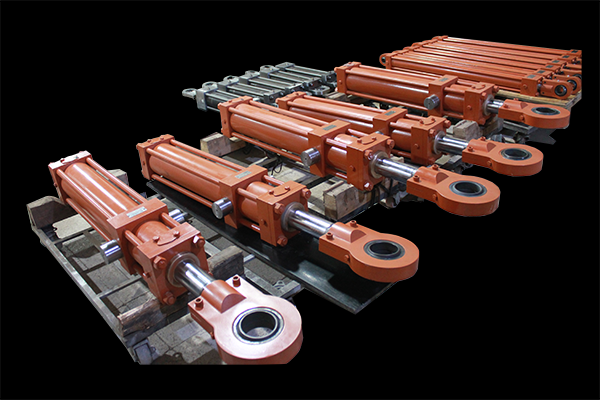

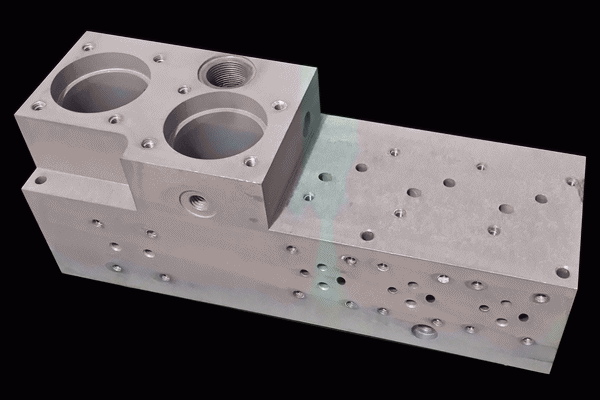

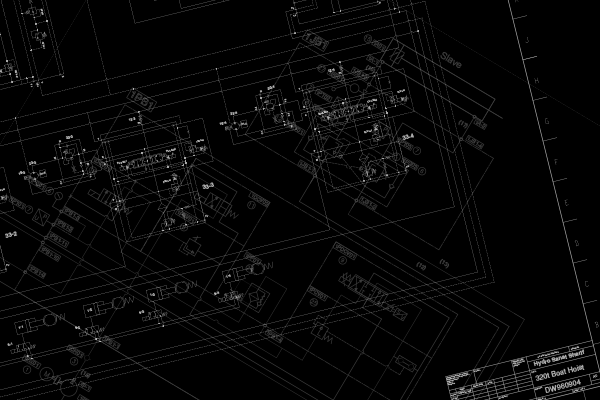

شرکت هیدرو صنعت شریف در حوزه های فنی شامل مکانیک (طراحی سازه، ساخت و هیدرولیک)، برق (الکترونیک و قدرت) و همچنین در حوزه های بازرگانی و تأمین قطعات فعال بوده و با تجارب کاری ارزنده به عنوان طراح و سازنده با بهره مندی از کارگاه ساخت و مونتاژ آماده ارائه خدمات می باشد. این شرکت با به کارگیری توانایی های کارکنان بخش مهندسی و بازرگانی در تلاش است تا علاوه بر فعالیت در زمینه های طراحی و اجرای پروژه ها، با اخذ نمایندگی و اجازه فروش برندهای معتبر جهانی در امور بازرگانی و فروش این محصولات به خریداران داخلی نیز مشارکت داشته باشد.

DC Motors, Drivers, Balls Screws, Linear Actuators, Shock Absorbers

موتور DC، بال اسکرو مینیاتوری، ضربه گیر و جاذب ارتعاشات، اکچویتور خطی

هیدرو صنعت شریف سعی کرده است تمامی نیازهای ساخت ماشین مخصوص شما را در یک جا ارائه نموده و بخشی از سیستم انتقال قدرت و کنترل شما باشد. موتورهای DC کوچک از بین برندهای مکسون، درایورهای خاص AMC، اکچویتور خطی تامسون و سرومک، ضربه گیرهای Enidine،